SERVICES

SEATEC provides high-standard underwater services 24/7.

We specialize in inshore and offshore underwater services, such as submarine pipelines, port projects, permanent and floating constructions, ships, floating jetties, yacht pontoons, hydroelectric dams, bridges, and other underwater projects.

SEATEC, provides underwater services with immediate response times throughout the Ionian Sea area such as:

Underwater Services Igoumenitsa

Underwater Services Corfu

Underwater Services Sivota

Underwater Services Plataria

Underwater Services Parga

Underwater Services Paxos

Underwater Services Lefkada

Underwater Services Preveza

Underwater Services Sayada

Underwater Services Kefalonia

Underwater Services Ithaca

Underwater Services Zakynthos

We also provide underwater project services throughout Greece, Europe and third countries abroad.

SEATEC is certified according to ISO 9001:2015, ISO 14001:2015 & ISO 45001:2018 by Bureau Veritas.

SEATEC is certified according to ISO 11666, ISO 10160, and ISO 17640, with an NDT Level 2 certification level, and is qualified to perform and supervise Underwater Non-Destructive Testing (NDT) in accordance with existing or recognized procedures.

INSPECTION MAINTENANCE REPAIR

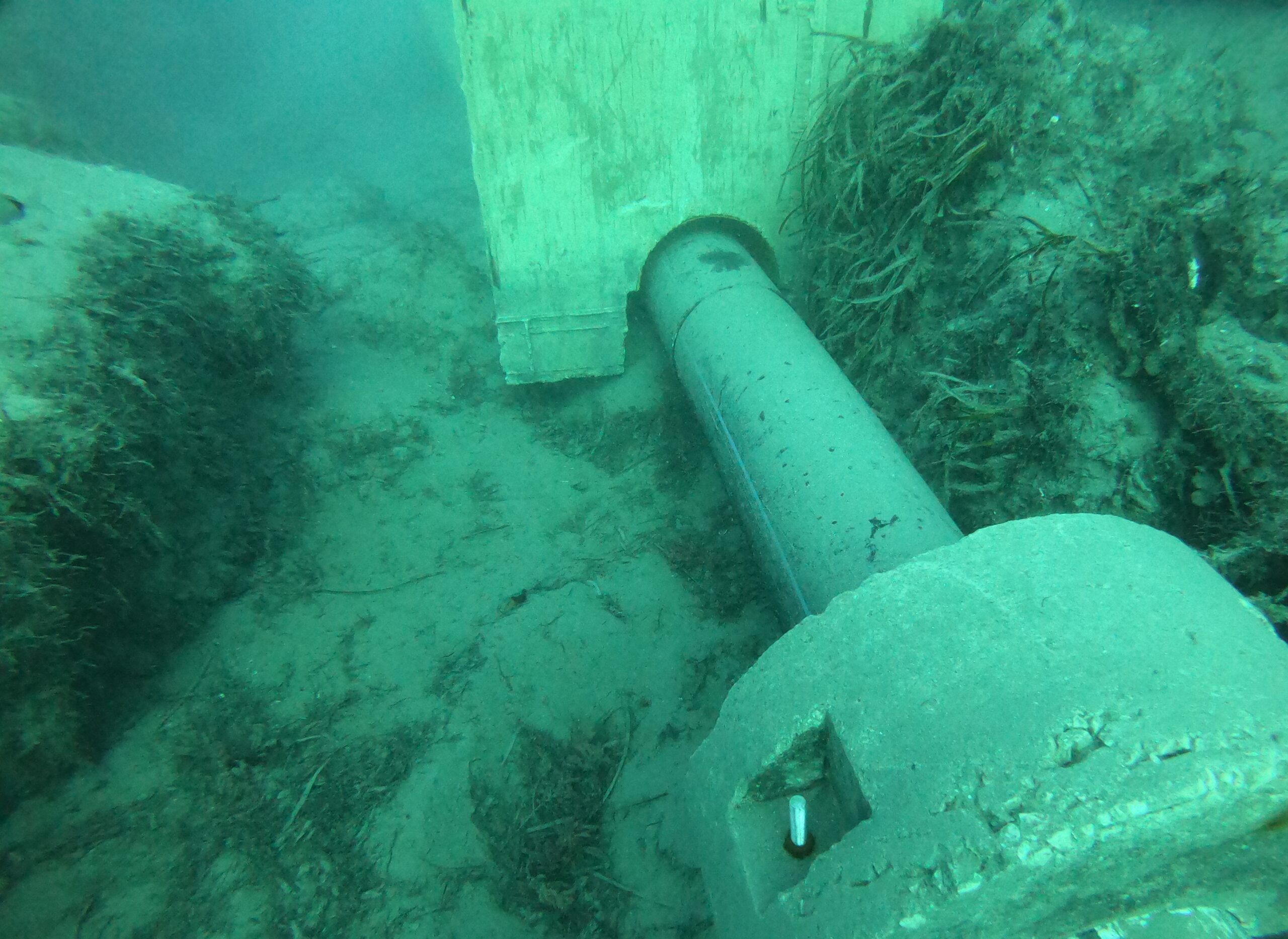

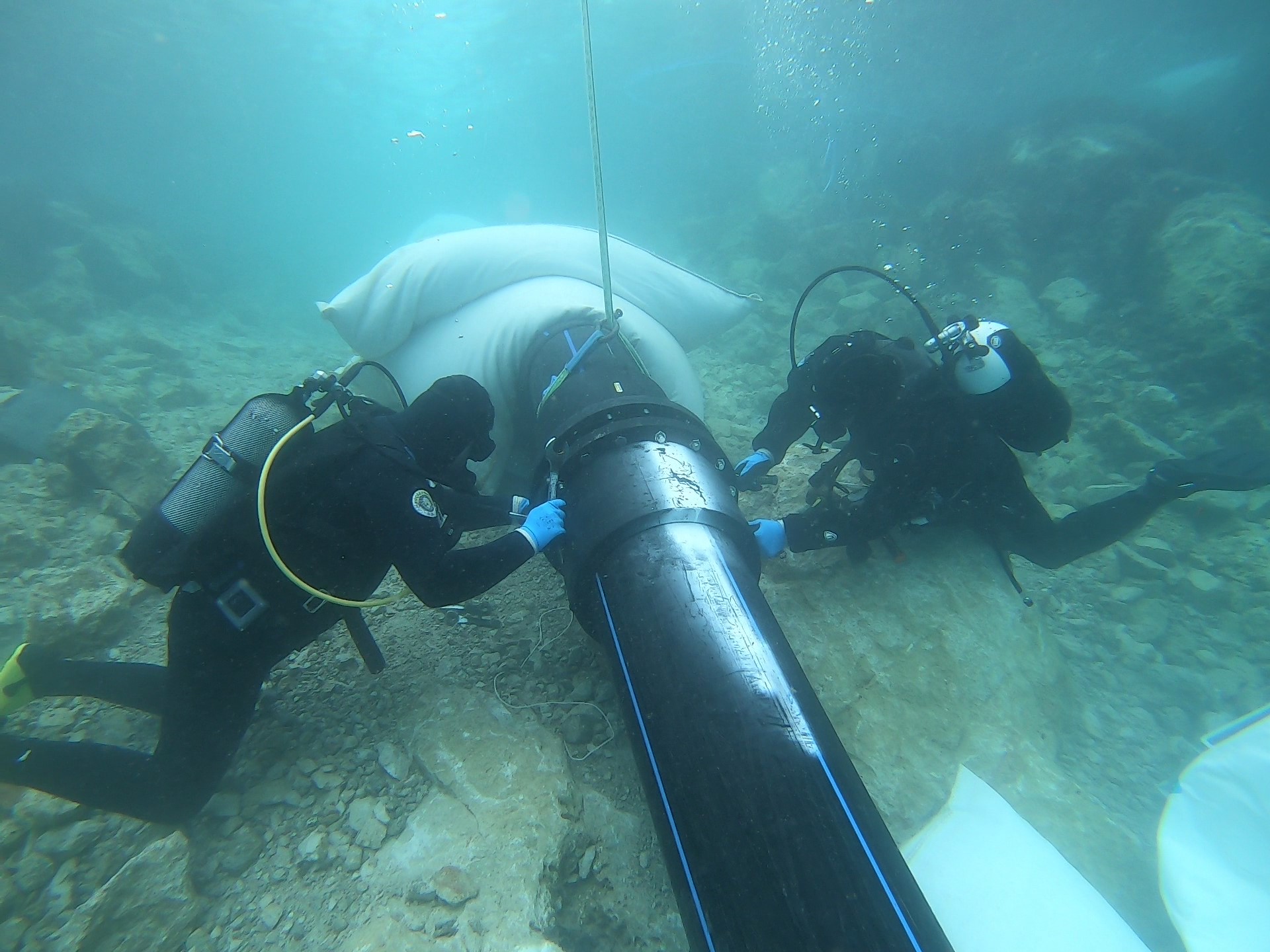

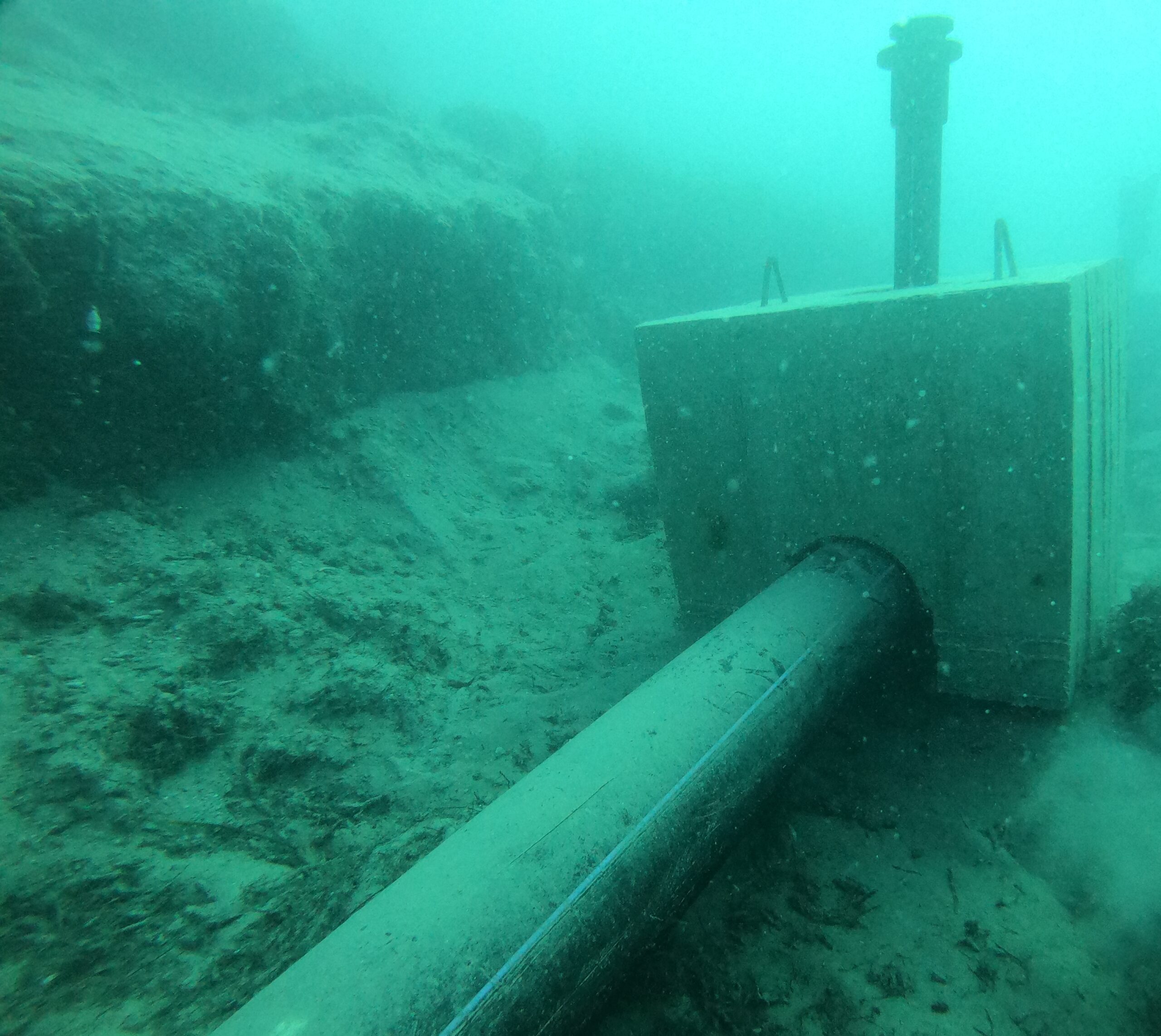

- UNDERWATER PIPELINES

- HULL VESSELS

- FLOATING STRUCTURES – PIERS

- MARINE CONSTRUCTIONS

- PORT INSTALLATION

- HYDROELECTRIC DAMS & STATIONS

- MARINE – WATER BRIDGE SKIDS

- ARTIFICIAL WATER CHANNELS

- INDUSTRIAL TANKS

- SUBMARINE BREAKWATERS

- HARBOR BREAKWATERS

- FLOATING BREAKWATERS

- SHIP PROPELLER

- SHIP RUDDER

- SHIP SHAFTS

- BOW THRUSTER

- HULL CRACKING

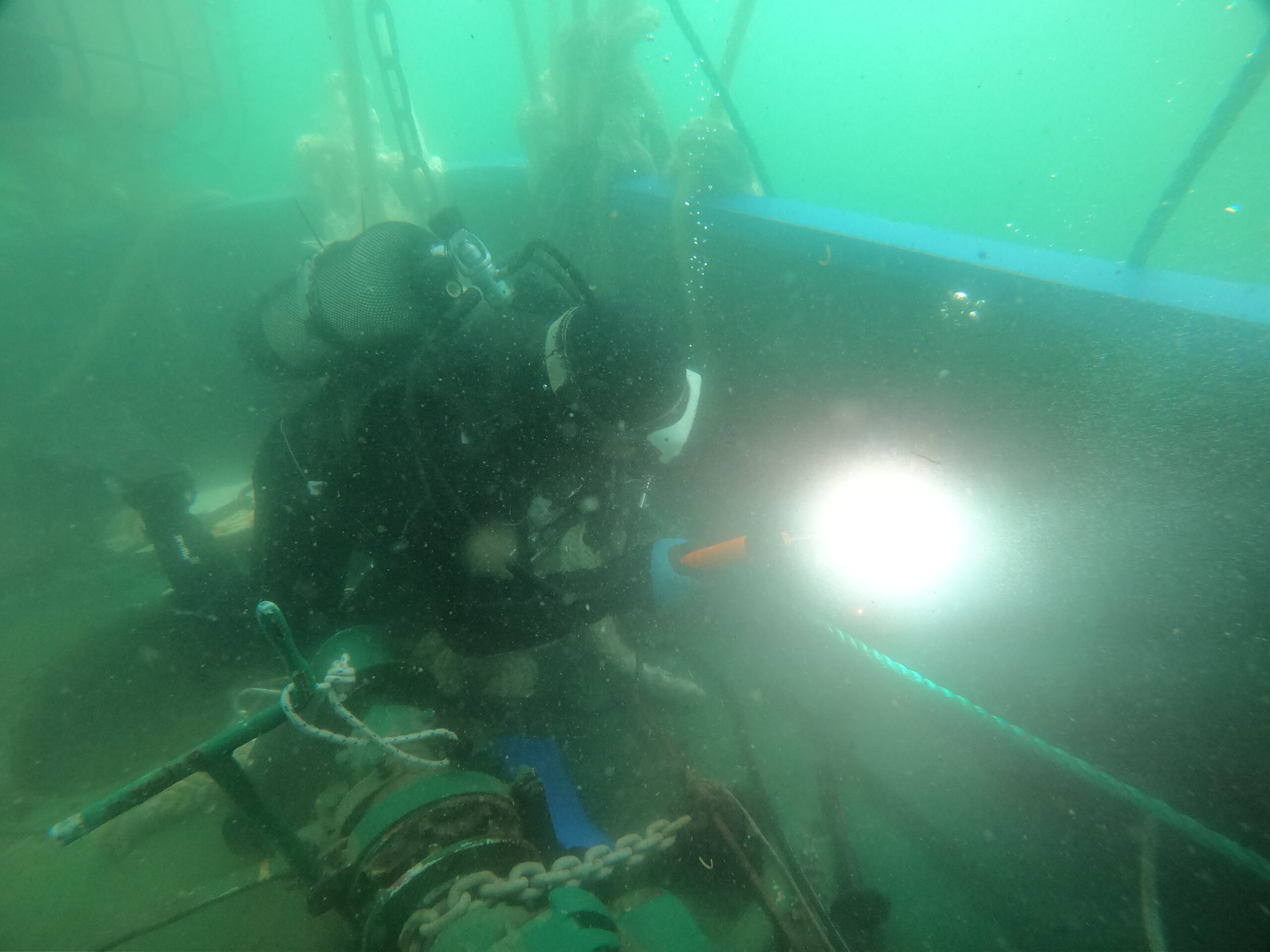

- UNDERWATER WELDINGS

- CATHODIC PROTECTIONS of MARINE STRUCTURES

- SHIPS ANODES

- PERMANENT MOORINGS

- DRY DOCKING EXTENSION

- SEARCH & INSPECTION for INSURANCE COMPANIES

- INSPECTION & WORK at GREAT DEPTHS using MIXED GAUSES (TRIMIX)

- INSPECTION & WORK of STRUCTURAL CONSTRUCTIONS at HIGH ALTITUDE

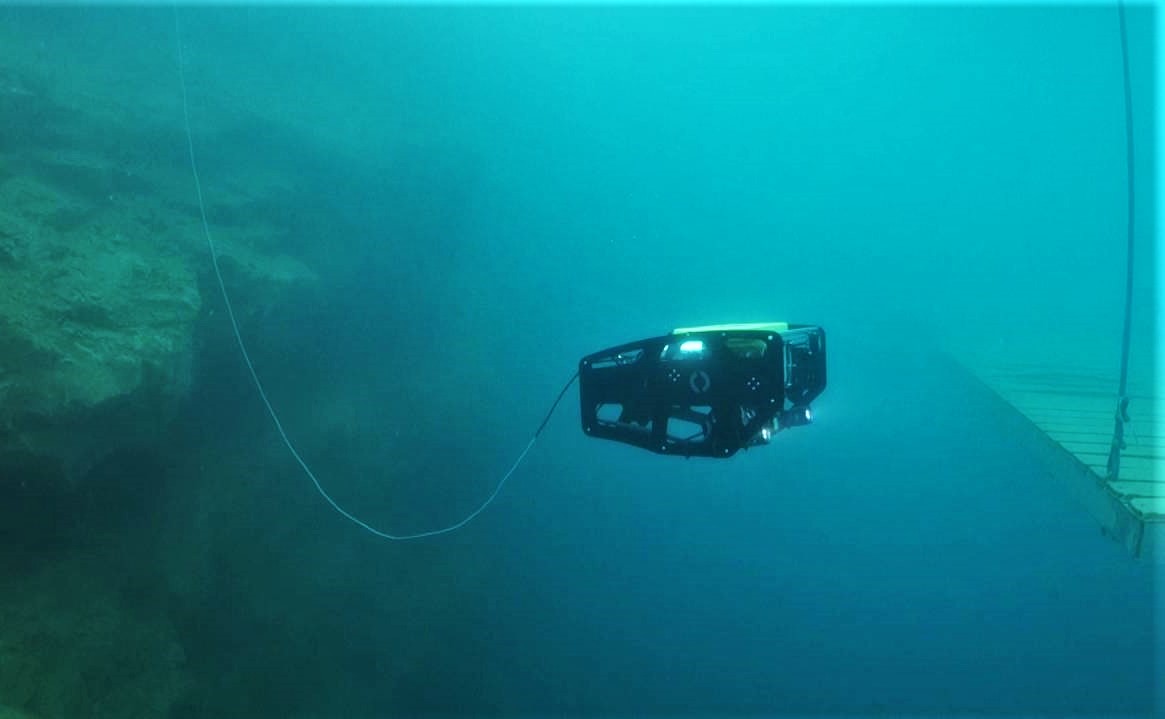

We have the possibility of Inspection with UNDERWATER R.O.V. in cases of Increased Risk due to Operational Depth or Adverse Environmental Conditions.

UNDERWATER SERVICE

- TOWING WRECKS – SHIPWRECKING

- SALVAGE

- SCIENTIFIC DIVES

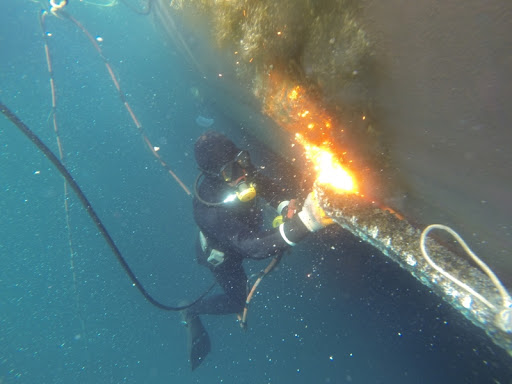

- UNDERWATER WELDING (with BROCO & FRONIUS)

- UNDERWATER CUTTING (with BROCO & FRONIUS)

- REHABILITATIONS – RESTORATION of KRIPIDOMA CAVE-INS

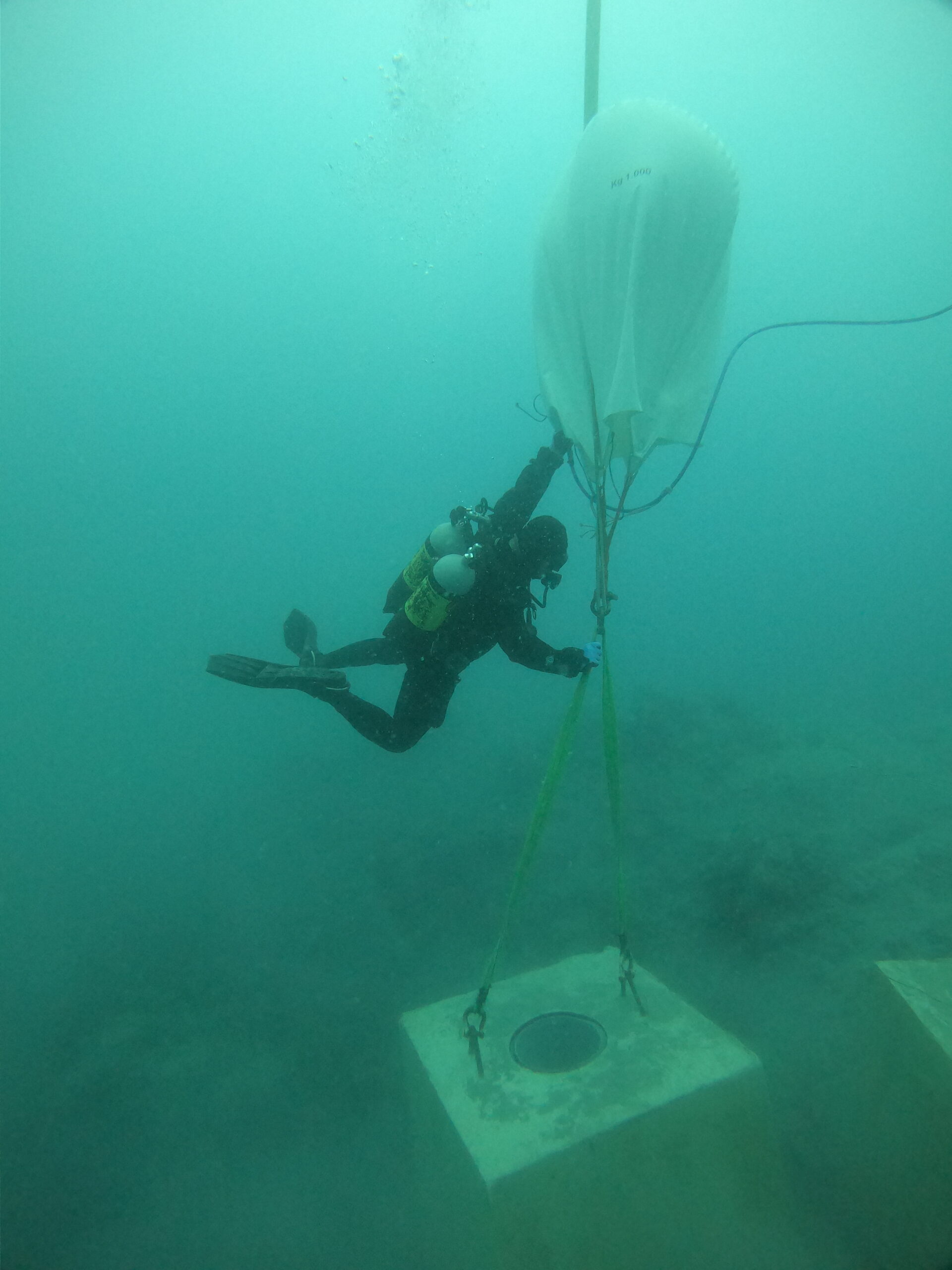

- LIFTING & LAUNCHING STRUCTURAL UNDERWATER CONSTRUCTIONS

- UNDERWATER SHIP PROPELLER REPLACEMENT

- UNDERWATER SHIP RUDDER REPLACEMENT

- UNDERWATER SHUFT SEALING (for SHIP ENGINE ROOM WORKS)

- UNDERWATER SUCTIONS SEALING (for SHIP ENGINE ROOM WORKS)

- INSTALL SHIP ANODES

- INSTALL CATHODIC PROTECTION of STRUCTURAL UNDERWATER CONSTRUCTIONS

- UNDERWATER FUEL PUMPING of SHIPWRECK

- UNDERWATER SEALING

- UNDERWATER CONCRETE CONSTRUCTION, LAYERING & FOUNDATIONS

- BEARING LAYER of RUBBLE

- REPAIR – RESTORATIONS of GUAYS & EMBANKMENTS

- INSTALLATION OF ANCHORAGES

- RECOVERY ANCHOR & METAL OBJECTS (with METAL DETECTOR)

- UNDERWATER BOTTOM SAMPLING

- UNDERWATER WATER SAMPLING

- PRACTICAL MANAGEMENT of MARINE POLLUTION

- CLEANING UNDERWATER PIPELINES & STRUCTURAL CONSTRUCTIONS

- UNDERWATER SAMBLASTING STRUCTURAL CONSTRUCTIONS

- UNDERWATER PROPELLER & RUDDER CLEANING

UNDERWATER TECHNICAL MEASURMENTS

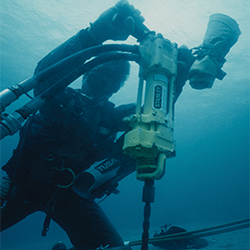

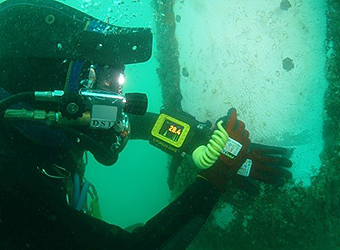

- THICKNESS MEASUREMENTS of ALL METAL TYPE

- THICKNESS MEASUREMENTS of UNDERWATER PIPELINE

- THICKNESS MEASUREMENTS of UNDERWATER STRUCTURAL CONSTRUCTIONS

- THICKNESS MEASUREMENTS of HULL SHIPS

- UNDERWATER MEASUREMENTS of POTENTIAL DIFFERENTS

- UNDERWATER MEASUREMENTS of SHUFT SHIP

- UNDERWATER MEASUREMENTS of SHIP RUDDER

- UNDERWATER WELDING INSPECTIONS with MAGNETIC PARTICLE METHOD – WEIGHT STANDARD CT3 CALIBRATION

CONSTRUCTIONS & INSTALLATION

-

UNDERWATER PIPELINES

-

UNDERWATER STRUCTURAL CONSTRUCTIONS

-

FLOATING STRUCTURAL CONSTRUCTIONS

-

FLOATING PIERS & DECKS

-

RUBBER PUMBER of PORT SUPERSTRUCTURE

-

PNEUMATIC FENDERS

-

PORT WATER BREAKERS

-

UNDERWATER BREAKERS

-

FLOATING BREAKERS

-

PERMANENT ANCHORAGE

-

SPECIAL STRUCTURES

SEARCH & RESCUE

-

UNDERWATER SEARCH – LOCATE & SECURE WAR MATERIAL

-

SURFACE – UNDERWATER SEARCH & RESCUE

-

UNDERWATER SEARCH & LOCATED MISSING PERSONS

-

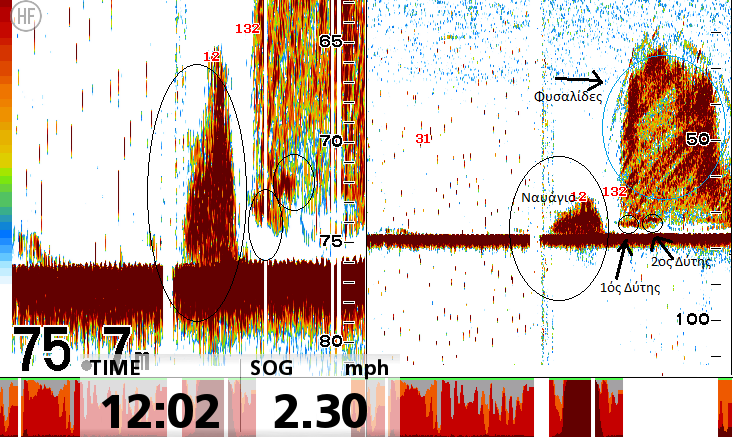

SEARCH & LOCATE SHIPWRECKS

-

SEARCH & LIFTING OBJECTS from HIGH DEPTHS

-

SEARCH & RESCUE CARGO SHIP – SALVAGE

-

SEARCH – INSPECTION & SURVEYING

-

WRECK CAUSE INVESTIGATION

-

UNDERWATER SEARCH & ESTIMATE for INSURANCE COMPANIES

We have the possibility of Inspection with UNDERWATER R.O.V. in cases of Increased Risk or Increased Cost due to Operational Depth or Adverse Weather Conditions.

TECHNICAL STUDY & PROJECT PLANNING

- PORT INSTALLATIONS

- FLOATING CONSTRUCTIONS

- FLOATING PIERS

- PERMANENT ANCHORANGE

- PORT WATERBREAKERS

- FLOATING WATER BREAKERS

- UNDERWATER WATER BREAKERS

- UNDERWATER PIPELINES

- SPECIAL STRUCTURES

UNDERWATER

NON-DESTRUCTIVE TESTING (NDT)

SEATEC has been certified with Level 2 Non-Destructive Testing by the “Welding & NDT Institute” and the “Hellenic Society for Non-Destructive Testing” (HELEMKE).

SEATEC is certified by ISO 11666, ISO 10160, and ISO 17640, and is qualified to perform and supervise Non-Destructive Testing (NDT) in line with existing or recognized procedures. They have demonstrated the ability to:

a) Select the appropriate technique for the testing method to be used.

b) Define the limitations of application for the testing method.

c) Understand NDT standards and specifications and translate them into practical testing instructions adapted to prevailing working conditions.

d) Operate and calibrate equipment.

e) Perform and supervise inspections.

f) Interpret and evaluate results in accordance with applicable standards, codes, or specifications.

g) Prepare written instructions for testing.

h) Perform and supervise all Level 1 responsibilities.

i) Classify and report NDT results.

j) Provide guidance to Level 1 and Level 2 personnel.

SEATEC performs the following methods of Underwater NDT Inspection using Level 2 Certified Diver Technicians:

-

Underwater Ultrasonic Thickness Measurements

-

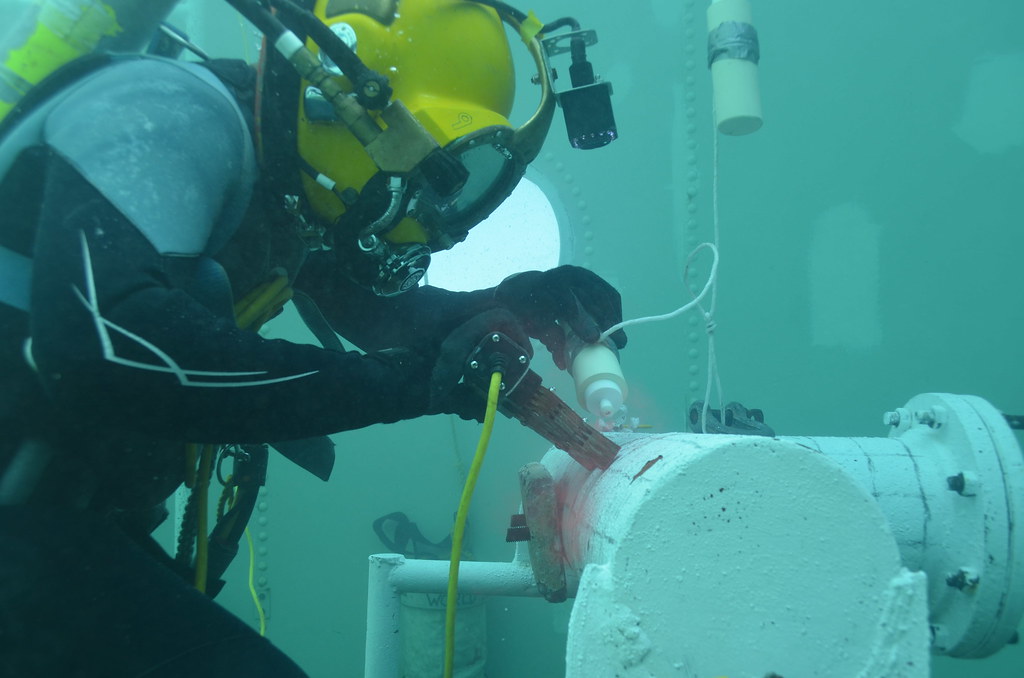

Underwater Magnetic Particle Inspection (MPI)

-

Underwater Eddy Current Testing

-

Underwater Visual Inspection

Recognized linear indications are documented using real-time underwater photography and video.

Underwater Ultrasonic Thickness Measurements

Underwater Ultrasonic Thickness Testing (UTT) is a well-established technique that enables accurate measurement of the thickness of metallic and other materials without requiring access to both sides of the material.

Ultrasonic testing provides high precision and rapid data acquisition, even under demanding conditions such as those found in underwater environments.

SEATEC is certified under ISO 9001:2015 by Bureau Veritas and RINA, scope of certification:

Ultrasonic Thikness Measurements

The application of the Underwater Ultrasonic Thickness Measurements (UTT) method to the underwater sections of a vessel or other metallic structural components aims to:

-

Evaluate corrosion damage caused by continuous exposure to the marine environment.

-

Ensure the structural integrity of the vessel or installation.

-

Comply with minimum thickness requirements as defined by international organizations and classification societies.

UNDERWATER WELD INSPECTION

Magnetic Particle Testing Method

(Underwater MPI)

Underwater Magnetic Particle Inspection (MPI) of Welds involves identifying the extent of cracks in ferrous metals that may not be visible to the naked eye.

Once the crack boundaries are detected, a drilling stop technique or other supplementary preventive measures are often required.

MPI crack testing can be performed in wet or dry conditions using UV crack detection systems combined with magnetic particle inspection (MPI), carried out by SEATEC’s trained personnel.

Some cracks may extend above the waterline, requiring MPI inspection both above and below the waterline. This is achievable with the MPI systems we utilize.

UNDERWATER CRACK DETECTION

Pulsed Eddy Current Method (PEC)

Underwater Crack Detection using Eddy Current (EC) is most effective for detecting surface-breaking cracks.

Its most practical applications are related to in-service inspection of welded structures subjected to cyclic loading, which may lead to the propagation of fatigue cracks in critical welded areas.

Eddy current testing is well-suited for identifying surface-breaking defects. It can detect such defects through relatively thick coatings (up to 2 mm). Underwater, multiple scans of a single weld are required to ensure no defect is missed.

Eddy current inspection is a diver-dependent technique.

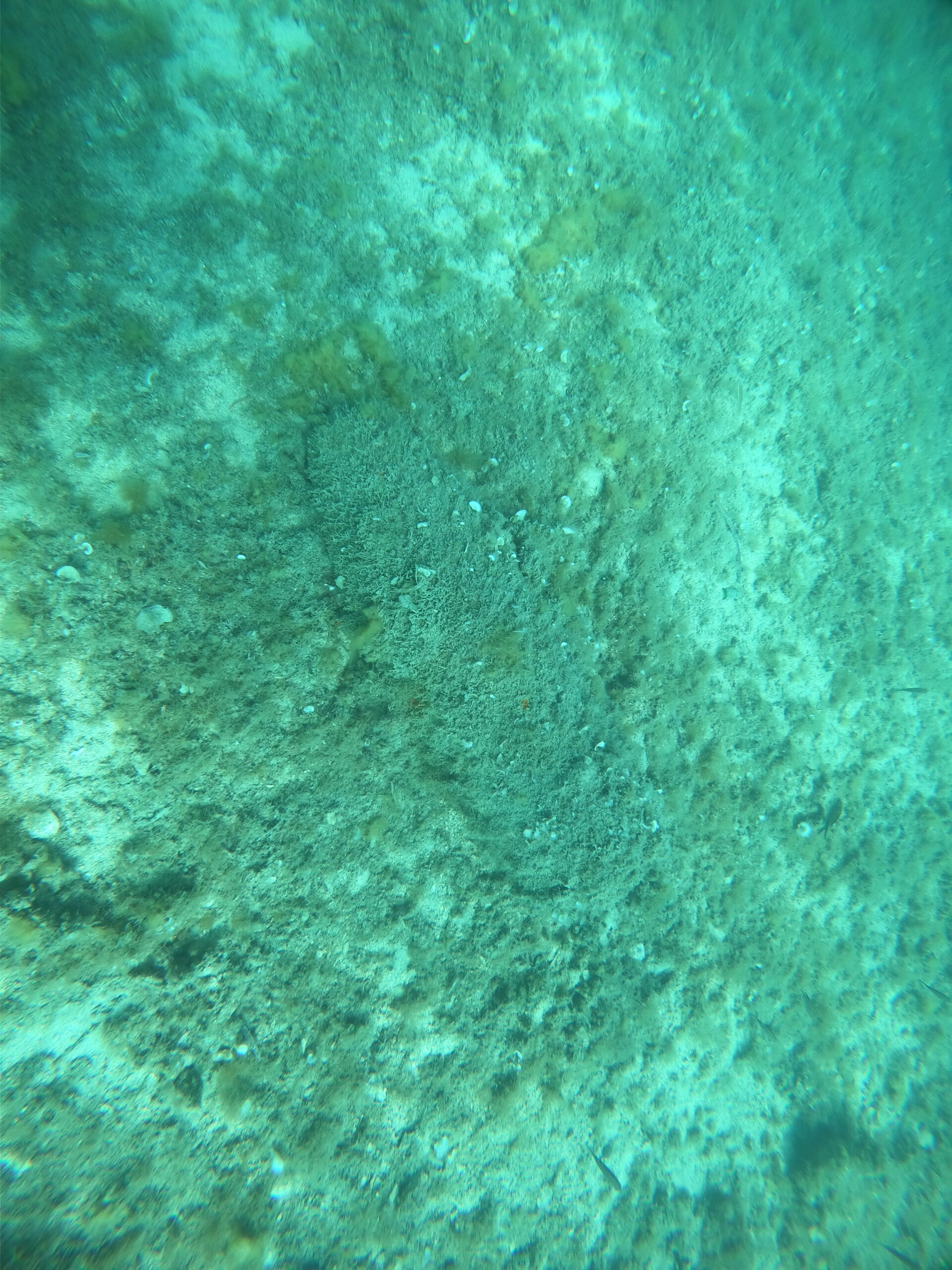

UNDERWATER VISUAL INSPECTION

Visual Inspection Method (VI)

Underwater Visual Testing (VT) for Non-Destructive Testing (NDT) is a method that involves the direct observation of a component to detect surface discontinuities. It is the simplest and most fundamental form of NDT, often serving as a preliminary step before the application of more complex methods.

VT can be performed with the naked eye or with the aid of optical instruments such as magnifying glasses, borescopes, and videoscopes.

The versatility of this method allows it to be applied across various industries and environments.

An NDT-certified diver from SEATEC applies field experience and expertise to select the appropriate technique for the task and is capable of evaluating findings using a variety of reporting formats.

SEARCH – LOCATE – IDENTIFICATION

& SECURE WAR MATERIAL

During the 2nd World War, bombs dropped by warplanes and mines from warships ended up on the seabed and remained silent witnesses to the duels that unfolded in the skies and seas of Greece.

Remnants of the 2nd World War, such as bombs, mines, grenades and explosives of all kinds, remain untouched at the bottom to this day, many of which are in working order.

SEATEC having incorporated the knowledge, skills and experience gained from the activities of the company’s owner through 20 years of training and missions in the American and Greek Navy, provides services for Locating, Identifying and Securing War Material.

If you perceive war material in a marine area of your exploitation or jurisdiction, the SEATEC Divers Team undertakes the management of the emergency and the process of informing the Competent Authorities. Once he has searched the sea area around the initial target for more munitions, becomes a reconnaissance of the munitions for the full and detailed briefing of the Authorities. Afterwards, the war material is secured to prevent its movement due to adverse weather conditions and the maritime area around the target or targets is demarcated to prevent the passage of boats and bathers. Data are also collected on the identity of the war material, its exact location, depth, and morphology as well as other data which will be included in the final report to the Competent Authorities.

SEATEC is certified according to ISO 9001:2015 by Bereau Veritas with scope of certification:

Research, localization identification & secure – setting of boundaries of war material

TRADE – SUPPLY

HARBOR & MARINA

SEATEC services are varied, starting from the initial study, the preliminary design of the layout of the floating yards and berths, the selection of the most suitable mooring systems to maximize functionality and safety, procurement, construction, inspection, maintenance up to the budget estimation of project costs.

They also include all the equipment of the ports and floating structures such as the design of the power supply systems, water, fire hydrants and the remote control of sockets and taps, bumpers of reconstructions, etc. We have all the necessary experience in the design of steel, aluminum, stainless steel, wood and reinforced concrete structures as well as in anchoring systems for floating structures and moorings.

We also offer services to investors during the preparation of the business plan, when it comes to new marinas or upgrading and reorganizing existing ports. SEATEC also undertakes the planning and identification of the most suitable location for boat mooring.

SEATEC’s services range from the simple supply of floating structures to the implementation of complex projects with an understanding of the needs of its customers.

The company has ISO 9001:2015 certification.

PROJECT STUDY & DESIGN

The collaboration with SEATEC starts from the initial design stage, clarifying the most suitable options according to the particularities of each project and the wishes of the customer.

The experience of more than 30 years of SEATEC and Shipbuilding Mechanical Engineer Skoura Eftychia and their dedication to the field of Shipping services and passion for the sea, result in the maximum technical and aesthetic level of construction.

Following the highest international standards and making the best possible use of the available sea space.

Our partner Shipbuilding Mechanical Engineer Skoura Eftychia will guide you so that your expectations converge with international standards and will prepare the submission file to the respective port authorities for the project permit application.

Our calculation studies are accurate and comply with all international standards to ensure prompt approval of licensing.

SUPERVISION – CONTROL – CONSULTING SERVICE

SEATEC is always at your disposal, whether for the supply of equipment, as well as to provide you with our know-how, which guarantees our customers the highest possible success of their installations.

Our services in each function may include consulting services related to the selection of complementary equipment, supervision of the production process, design of production facilities, planning and organization of installation procedures and verification of compliance with the specifications of each project.

SEATEC is always next to each customer and supports them with all the necessary technical and operational means, as you would expect for a professional technical partner.

INSPECTION – MEINTENANCE & REPAIR

Technology in design and construction processes requires that floating structures have high-quality materials, consequently extending the life of the structures. Nevertheless, to ensure the smooth operation of the marina or port as well as the good condition of the floating structures, the managers must carry out regular inspections and periodic maintenance of the fixed and floating structures according to their use.

The inspection of the elements on the surface and underwater often reveals the need for an operation such as the tightening of links, the replacement or restoration of parts subject to natural wear, or the replacement of part of the mooring of structures or vessels, which when identified in time prevents the high and damaging repairs in the future.

SEATEC provides customers with inspection, maintenance and repair services.

SeaTec

Mastering the sea

CONTACT

Mob. 24/7:

- CEO SEATEC

(+30) 699 7020612 – Marketos Alexandros

- SEATEC DIVE TEAM MANAGER

(+30) 6977366707 – Kiriakidis Christoforos

- NAVAL & MECHANICAL ENGINEER NTUA

(+30) 6987070760 – Skoura Eftichia

Email: dive@seatec.gr

ADRRESSE

IGOUMENITSA

P.C. 46100

GREECE